Main characteristics and functions of machine

1. Machine drive adopt separation drive,and wheel sets are driven by spindle

simultaneously. Two suits of arc claw bite wheel sets on each faceplate.

2. The longitudinal and lateral movement of tool carriage is driven by CNC methods. Automatic processing can be realized by inputting (manual operation) diameter and related parameter.

3.Tool carriage is equipped with Swedish SANDVIK special-purpose tools of railway,and it

can realize better result and lower the cost during machining. Facing tool should be

replaced while machining the inside of wheel sets.

4.Tool carrier equipped with special tools for machining and repairing inner brake disc of wheel sets.

5.The machine is equipped with special-purpose tooling for machining the wheel sets profiles, journals and inside of locomotives.

6.The machine is mature products of our company, manufacturing material meet the related safety,environmental standards of the State and Industry, and quality of products is controlled by the ISO9001-2000 Quality System. We guarantee to provide products with advanced technology,reliable performance,reasonable structure,safety,environmental protection to our customers.

7.The machine has functions of wheel outline curve programming,machining,memory,display, and also has functions of safety protection,preventing the false operation,alarm display.

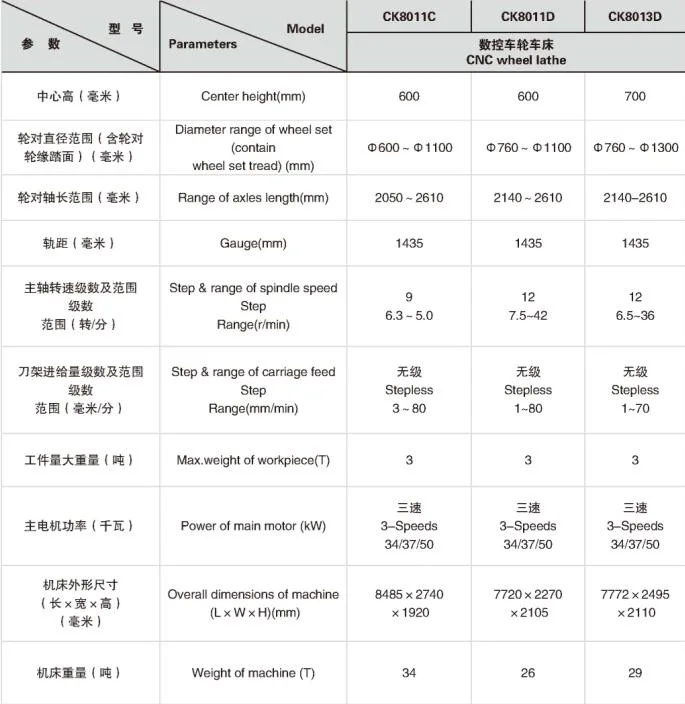

Main specification and parameters

simultaneously. Two suits of arc claw bite wheel sets on each faceplate.

2. The longitudinal and lateral movement of tool carriage is driven by CNC methods. Automatic processing can be realized by inputting (manual operation) diameter and related parameter.

3.Tool carriage is equipped with Swedish SANDVIK special-purpose tools of railway,and it

can realize better result and lower the cost during machining. Facing tool should be

replaced while machining the inside of wheel sets.

4.Tool carrier equipped with special tools for machining and repairing inner brake disc of wheel sets.

5.The machine is equipped with special-purpose tooling for machining the wheel sets profiles, journals and inside of locomotives.

6.The machine is mature products of our company, manufacturing material meet the related safety,environmental standards of the State and Industry, and quality of products is controlled by the ISO9001-2000 Quality System. We guarantee to provide products with advanced technology,reliable performance,reasonable structure,safety,environmental protection to our customers.

7.The machine has functions of wheel outline curve programming,machining,memory,display, and also has functions of safety protection,preventing the false operation,alarm display.

Main specification and parameters

1Gauge....................................… 1435mm

2Diameter range of wheel sets...............… φ750~1100 mm

3Diameter range of wheel set chucking............φ690~900 mm

4Range of axial length.....................…1700~2030mm

5Range of wheel tyre width..................… 120~140mm

6Max. weight of workpiece........................3000Kg

7Step of spindle speeds...........................…12

8Range of spindle speeds.....................7.5~42r/min

9Diameter of chuck...........................…1100 mm

10Numbers of coordinate axis ............…(X axis,Z axis) 2

11Step of carriage feed........................…stepless

12Range of carriage feed(common)

lateral(X)...........................0.5~2mm/r

longitudinal(Z)........................0.5~2mm/r

13Main motor power...........................34/37/50KW

Synchronous speed..................750/1000/1500r/min

14CNC system..................… SINUMERIK 828D(two sets)

15AC servo motor........................ 1FK7101(4)

torque:18N.m rotational speed:3000 r/min

16Overall dimensions of machine(L×W×H)...…7720×2740×1900mm

17Total power of machine........................115KVA

18Total weight of machine........................…30T

19Machine noise...........................…≤83dB(A)

Machining accuracy and working efficiency

1 Wheel Profile(surface error) ...............… ≤0.2mm

2 Diameter difference of same wheel set............… ≤0.2mm

3 Wheel profile jumping........................ ≤0.2mm

4 Medial surface jumping........................≤0.3mm

5 Machine surface roughness..................…Ra≤12.5μm

6 Productivity..................15wheel set/time(8 hours)

7 Dimension and accuracy of wheel profile meet TB1967-87 requirement